Unlocking Efficiency: The Power of a Barcode Label Maker for Your Business

In today’s fast-paced business environment, efficiency is paramount. One of the most effective tools to enhance operational workflows is the barcode label maker. This device not only helps in organizing products, but it also aids in inventory management, streamlining sales processes, and improving overall productivity. In this comprehensive guide, we will delve into the various facets of barcode label makers, their significance in different industries, particularly in printing services and electronics, and how they can propel your business to new heights.

Understanding Barcode Label Makers

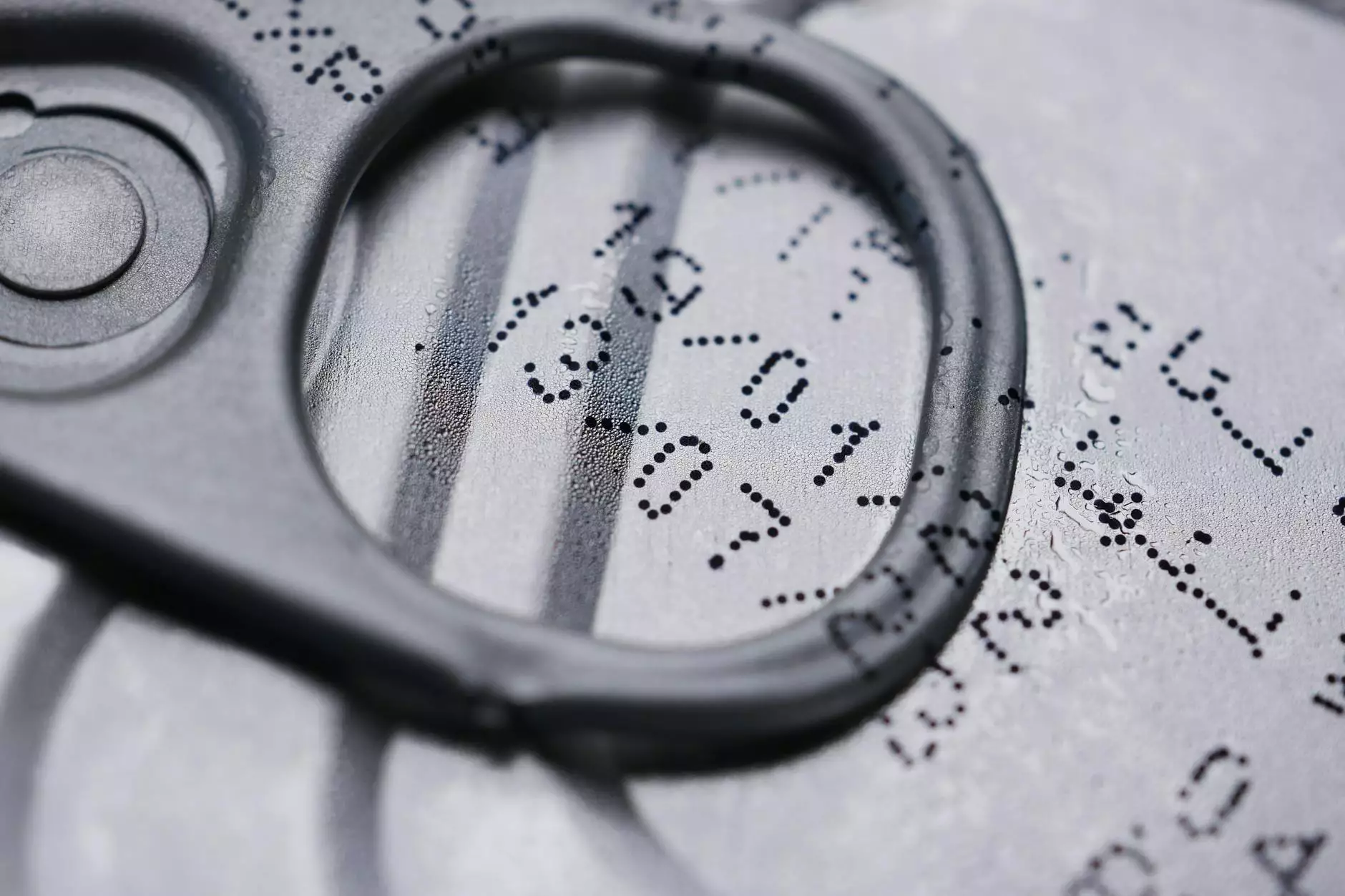

A barcode label maker is a specialized device that prints labels with unique codes that can be read by scanners, allowing for quick identification of items. This technology has transformed how businesses manage their inventory and sales processes.

Types of Barcode Label Makers

When selecting a barcode label maker, it's essential to understand the different types available:

- Desktop Barcode Label Makers: Ideal for small to medium-sized businesses, these devices are user-friendly and often have a compact design.

- Industrial Barcode Label Makers: These heavy-duty machines are built for high-volume printing and are designed to withstand harsh conditions.

- Mobile Barcode Label Makers: These portable options allow employees to print labels on the go, improving flexibility and efficiency.

- Online Barcode Generators: Software solutions that allow users to design and print barcodes using a standard printer.

Benefits of Using a Barcode Label Maker in Your Business

Integrating a barcode label maker into your operations can yield numerous benefits. Here are some key advantages:

1. Enhanced Accuracy

Manual data entry is prone to human error. By using barcodes, you can significantly reduce mistakes, as scanning is more accurate than typing.

2. Increased Efficiency

Barcode scanning drastically reduces the time spent on inventory management and sales processes, allowing employees to focus on more critical tasks.

3. Improved Inventory Management

Utilizing a barcode label maker helps in tracking stock levels in real-time, providing valuable insights into inventory turnover rates and stock shortages, ensuring that your business operates smoothly.

4. Cost-Effective Solutions

While there is an upfront investment in barcode printers, the savings from reduced labor costs and improved accuracy will quickly outweigh initial expenses.

5. Streamlined Sales Processes

In retail, speedy checkout processes are crucial. Barcode scanners allow for quick sales transactions, enhancing customer satisfaction.

Applications of Barcode Label Makers in Industries

The versatility of barcode label makers means they can be used across various industries. Let’s explore how they benefit the printing services and electronics sectors:

In Printing Services

For businesses in printing services, a barcode label maker is invaluable. Each print job can be assigned a unique barcode, allowing for precise tracking throughout the production process. This application is essential for:

- Job Tracking: Easily monitor the status and changes in each print job.

- Inventory Control: Keep an accurate count of printed materials, reducing waste.

- Client Management: Automate and streamline client order fulfillment with unique barcodes for each client’s job.

In Electronics

The electronics sector benefits from barcode label makers by ensuring effective tracking of components and finished products. Some applications include:

- Inventory Management: Maintain accurate inventories of parts and products.

- Shipping and Receiving: Speed up the logistics process by labeling products for tracking during shipping and warehousing.

- Product Identification: Ensure that every electronic device can be uniquely identified for warranty and service purposes.

Choosing the Right Barcode Label Maker

Deciding on the right barcode label maker for your business requires consideration of several factors:

1. Print Quality

Evaluate the print resolution and quality of the barcode. Higher DPI (dots per inch) settings produce clearer, more scannable barcodes.

2. Speed

Consider how fast the printer can produce labels. A faster printer can significantly improve workflow in busy environments.

3. Compatibility

Ensure the label maker is compatible with your existing software systems. Some printers come with proprietary software, while others are more versatile.

4. Label Features

Different businesses may require different label sizes, adhesive types, and materials. Choose a printer that can accommodate your specific needs.

5. Cost and Maintenance

Consider both the initial investment and the ongoing costs of supplies. Ensure the printer is cost-effective over the long term.

Getting Started: Integrating a Barcode Label Maker into Your Business

Once you’ve chosen a barcode label maker, integrating it into your business involves several steps:

1. Training Staff

Ensure that your staff is trained on how to effectively use the barcode label maker. This training should include both operation and troubleshooting.

2. Creating Barcodes

Utilize software to generate barcodes for your products. Ensure that the barcode format you choose is standard in your industry.

3. Implementing Scanning Systems

Integrate barcode scanners into your workflow, linking them to your inventory management software for seamless tracking.

4. Regular Updates and Maintenance

Keep your software and hardware updated to ensure optimal performance and security.

Case Studies: Success Stories with Barcode Label Makers

Many companies have successfully integrated barcode label makers into their operations. Here are a couple of examples:

Case Study 1: A Small Printing Service

A small printing company faced difficulties in tracking multiple client orders. By implementing a barcode system, they were able to track each job in real-time, improving their order fulfillment accuracy by 30% and reducing delivery times.

Case Study 2: An Electronics Retailer

An electronics retailer struggled with inventory discrepancies, leading to lost sales. By utilizing barcode label makers, they established a reliable inventory management system that decreased stock discrepancies by 50% and improved customer satisfaction.

Conclusion

In conclusion, a barcode label maker is not just a tool but a game-changer for businesses in the printing services and electronics sectors. Its ability to enhance efficiency, accuracy, and productivity is invaluable. With the right knowledge and tools, you can unlock the full potential of your business, paving the way for success and continued growth. Don’t hesitate to invest in this transformative technology; it could be the decision that takes your operations to new heights.

Frequently Asked Questions (FAQs)

1. What types of barcodes can I print with a barcode label maker?

You can print various types of barcodes, including UPC, QR codes, Code 128, and more, depending on the printer's capabilities.

2. Do I need special software to create barcodes?

Some barcode label makers come with proprietary software; however, many also support third-party applications for barcode creation.

3. Can barcode label makers print labels in different sizes?

Yes, most barcode label makers are adjustable and can print labels in various sizes to meet your needs.

4. How often should I replace my label maker’s supplies?

This depends on usage, but it is crucial to monitor supply levels regularly to prevent running out during critical business operations.

5. Are barcode label makers easy to use?

Most barcode label makers are designed to be user-friendly, allowing even non-technical staff to operate them efficiently after proper training.